WisTex

textile inspection

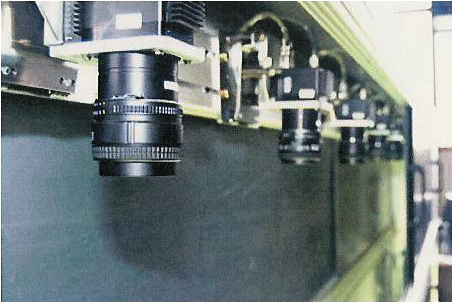

The WisTex project deals with developing an automatic grey goods inspection system in order to discover defects in patterned and structured as well as non-structured fabric in the production line.

Project partner Mahlo GmbH&Co KG has established itself as the global market leader for high tech systems in the textile and non-wovens industry for several decades. Ensuring the quality and inspection of fabric is a major focus of the portfolio of Mahlo.

Mahlo's fabric inspection system WIS-12 currently only supports the defect detection in non-structured fabric limiting its use to a small percentage of today's industrial fabric.In practice, perching for these fabrics is still done manually.

WisTex is aimed at closing those gaps. On the one hand we will develop and test methods to provide a measure of quality for the inspection of structured and patterend fabric. Thisprocess should be enhanced step by step in order to increase the fault detection rate. On the other hand we will research and develop relevant methods that later can be integrated into thesystem and allow an easy "teach-in" process. For example, when changing cloth runs the software should be able to learn and adopt to a new pattern after a short warm-up phasewithout human interaction.

With a fabric width of up to 5 meters and speed of approximately 100 meters per minute this vast amount of data needs to be handled very efficiently. All algorithms and methodstherefore shall be tested on their applicability in real-time inspection on the machines and computation time needs to be minized.