3D Printing of Huge Elements

Development of a New Technique for the Production of Huge Molds using 3D Printing

In this research project, a 3D printer for particle materials with a print volume of 4 meter x 2 meter x 1 meter has been developed and new control techniques and software tools have been investigated.

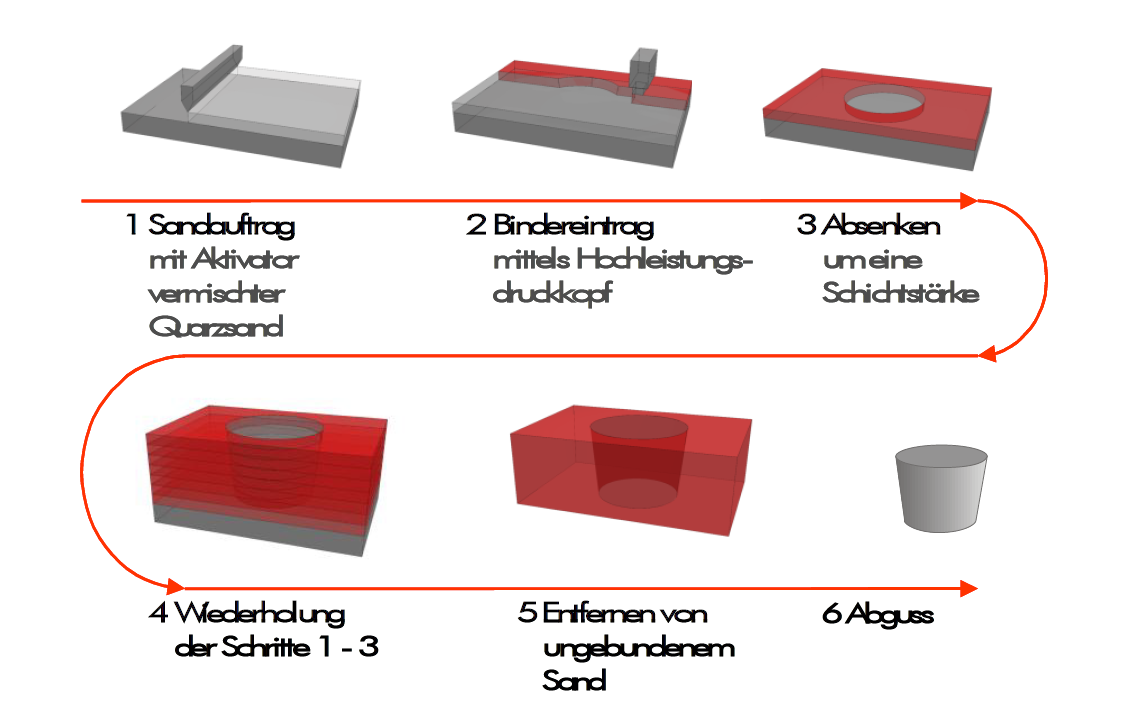

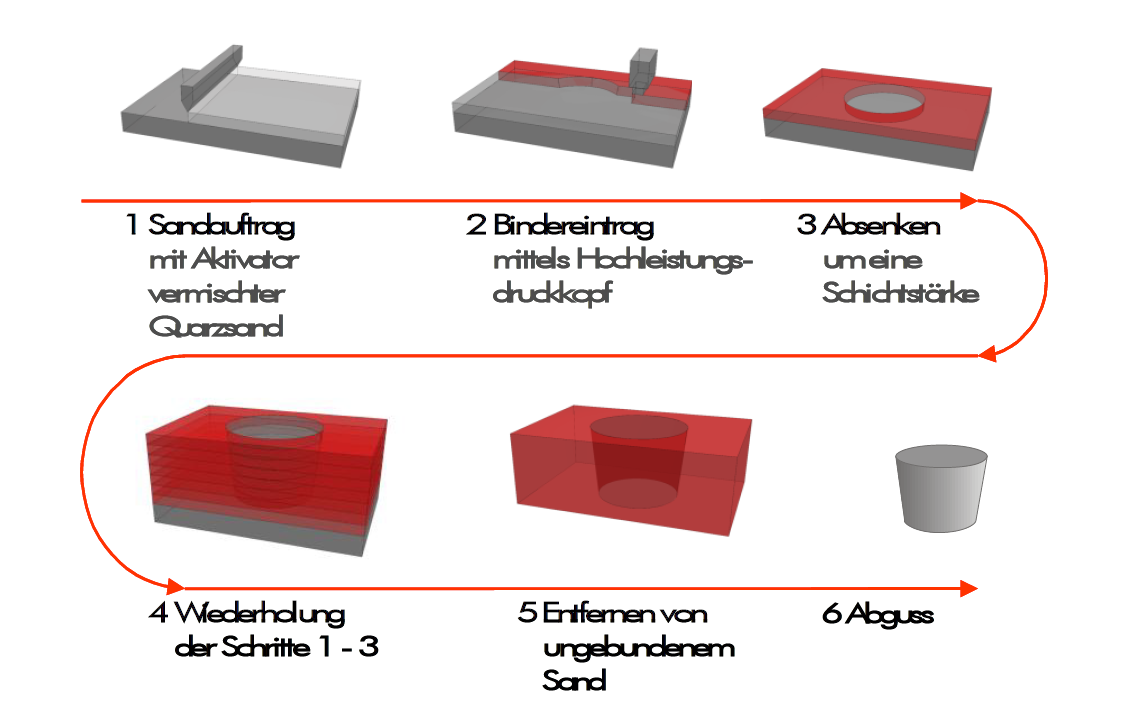

The 3D printing process is an additive manufacturing method. 3D printers build three-dimensional objects of CAD data using bonded powder, such as bonded sand or plastic. First the printer coats a layer of powder. Where the object is located, binder is injected by using a print head. Then, the top level is lowered by the layer thickness. These steps are repeated. After completion of the printing process, excess material is removed and the printed object can be processed further. That way e. g. molds for the production of metallic components or by infiltration stable objects may be fabricated.

|

| Schematic representation of the 3D printing process (From: voxeljet technology GmbH, Augsburg) |

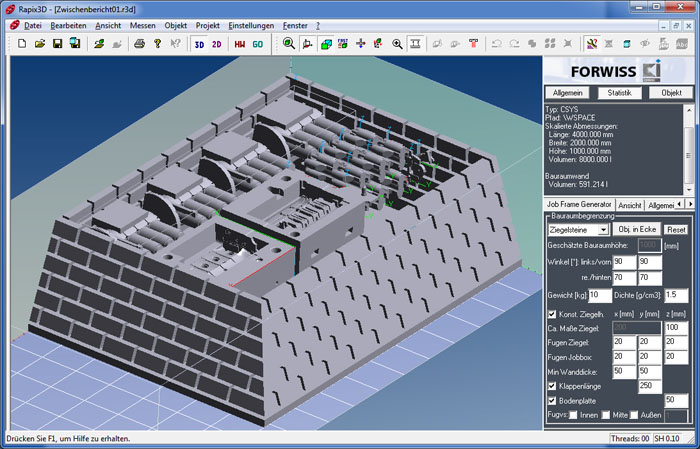

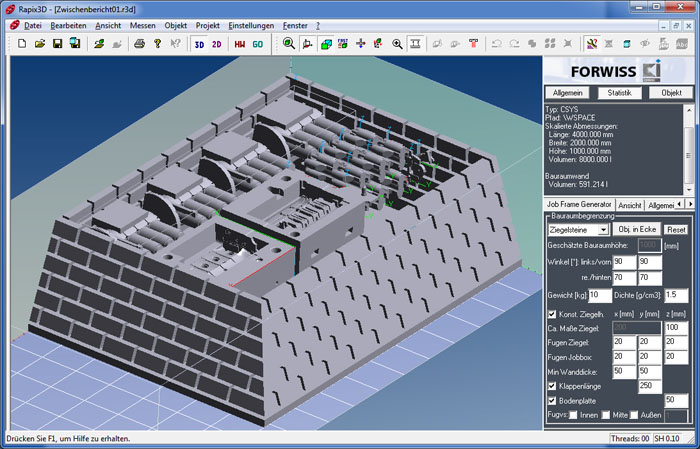

Our software system Rapix3D for rapid prototyping systems is developed at FORWISS since 1998. It allows placement of CAD objects in the building space of the printer, calculation of an image for each layer and controlling of 3D printers.

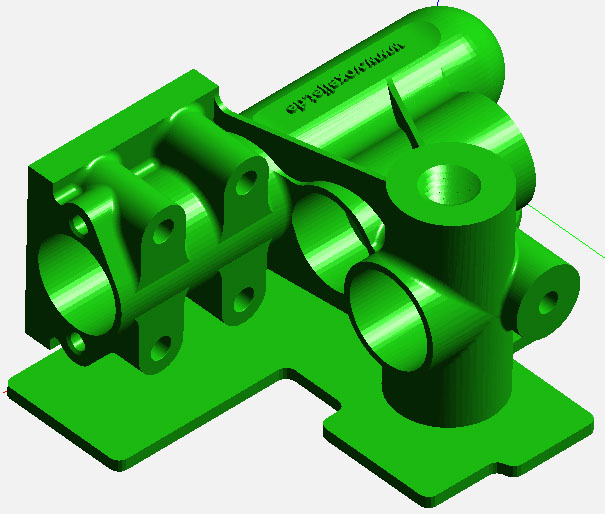

Molds are used for the production of work pieces especially made out of metal. To do so, a mold of sand is produced using a 3D printer and afterwards it is filled with a liquid material (e. g. metal). After it has solidified, the sand is removed. This method is suitable especially for the production of prototypes, such as in the automotive industry. Large-sized work pieces such as marine propellers could not previously be produced with this technique. Therefore, a huge printer using particle material with a 4 meter x 2 meter x 1 meter print volume was developed and new control techniques and software service tools were explored.

|

| Prototyp VX4000 produced by voxeljet GmbH, Augsburg (Foto: voxeljet technology GmbH, Augsburg) |

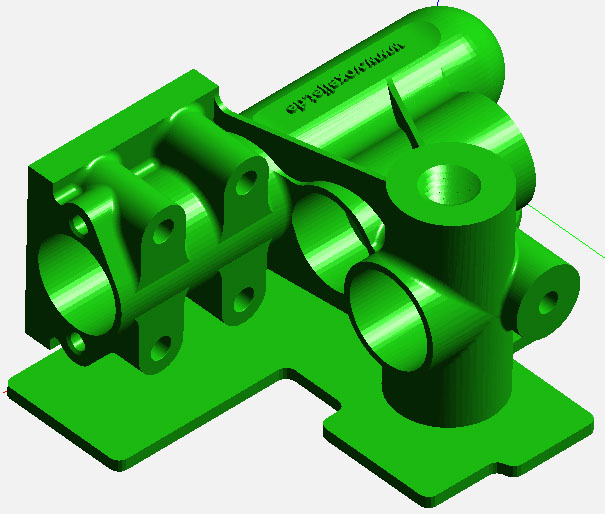

The efficient use of the huge print volume was made possible by numerous changes to the software Rapix3D and the exploration of novel software tools. For example a permanent wall to limit the print volume is no longer possible due to the mechanics of the printer. It is now generated as parameterized wall using Rapix3D. Also, this huge print volume is not unpacked from above, but it is unpacked from the side. Therefore, software tools were developed to support the unpacking process. Also, resource saving techniques have been developed, such as an automatically volume optimization of the print volume.

|

|

Rapix3D with huge print volume and wall

|

A separator panel that is adjusted to the CAD object created with Rapix3D |

In collaboration with voxeljet technology GmbH a large-sized 3D printer could be developed in this research project.

| Supported by: Federal Ministry for Economic Affairs and Technology on the basis of a decision by the German Bundestag |

|

|

|

Project staff