Printing of Green Bodies for Cemented Carbide

Developing of a Continuous 3D-Printing Process for Green Bodies for the Production of Cemented Carbide

In this project, a 3D printing system for printing cemented carbide, was developed in partnership with voxeljet technology GmbH (now voxeljet AG) and staegi GmbH, both Augsburg, Germany.

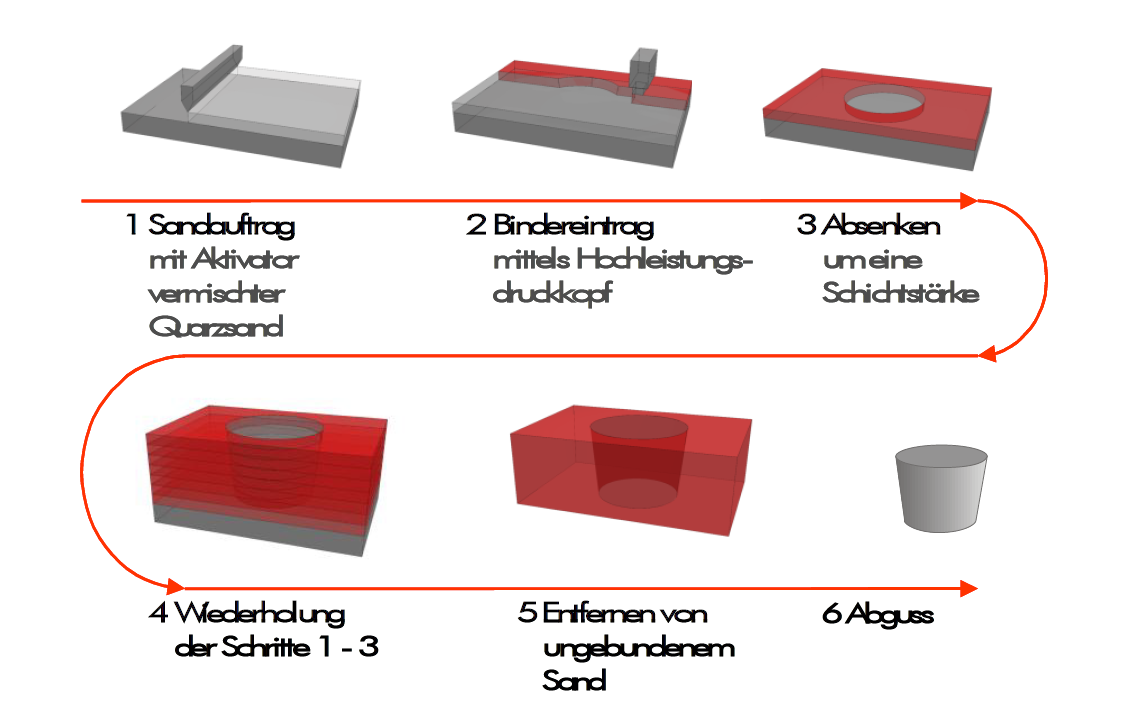

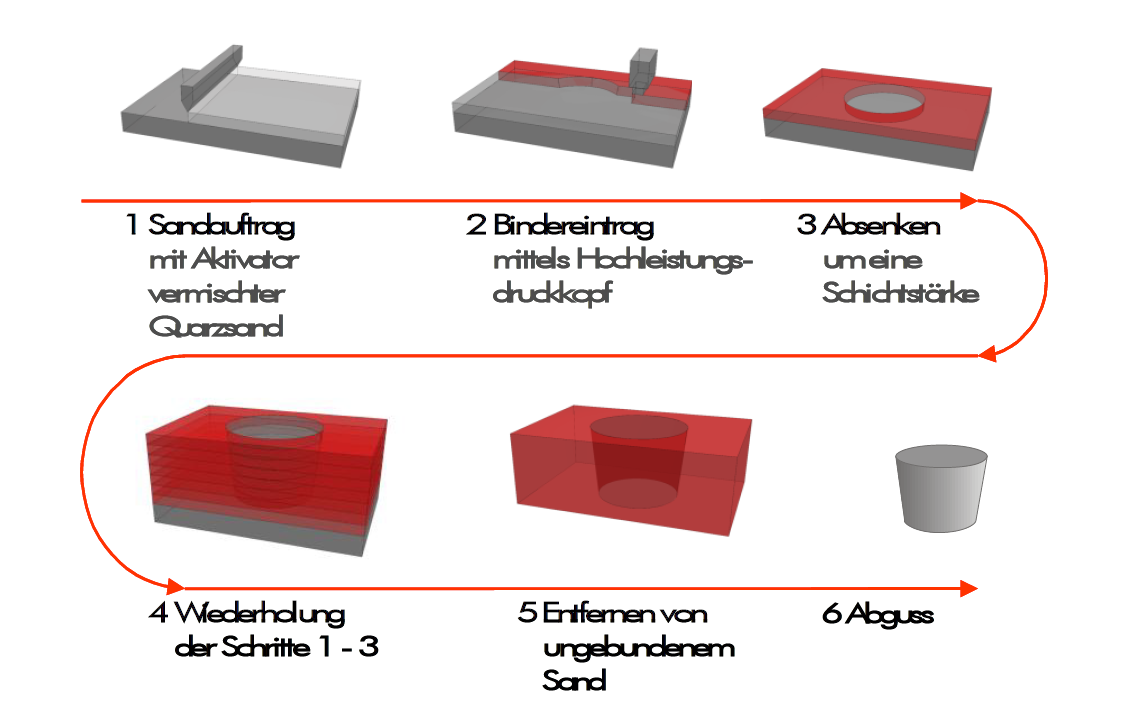

The 3D printing process is an additive manufacturing method. 3D printers build three-dimensional objects of CAD data using bonded powder, such as bonded sand or plastic. First the printer coats a layer of powder. Where the object is located, binder is injected by using a print head. Then, the top level is lowered by the layer thickness. These steps are repeated. After completion of the printing process, excess material is removed and the printed object can be processed further. That way e. g. molds for the production of metallic components or by infiltration stable objects may be fabricated.

|

| Schematic representation of the 3D printing process (From: voxeljet technology GmbH, Augsburg) |

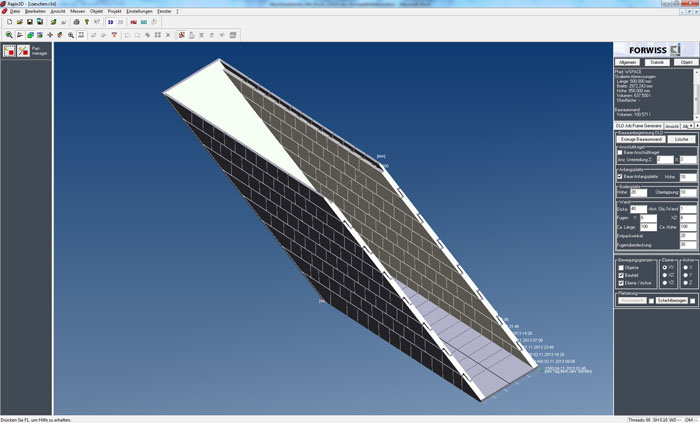

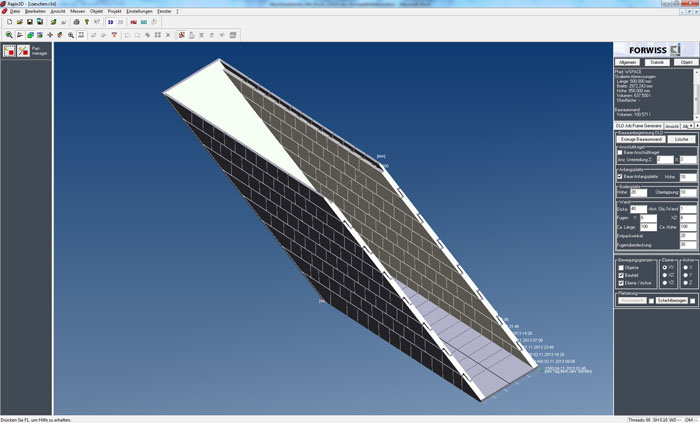

Our software system Rapix3D for rapid prototyping systems is developed at FORWISS since 1998. It allows placement of CAD objects in the building space of the printer, calculation of an image for each layer and controlling of 3D printers.

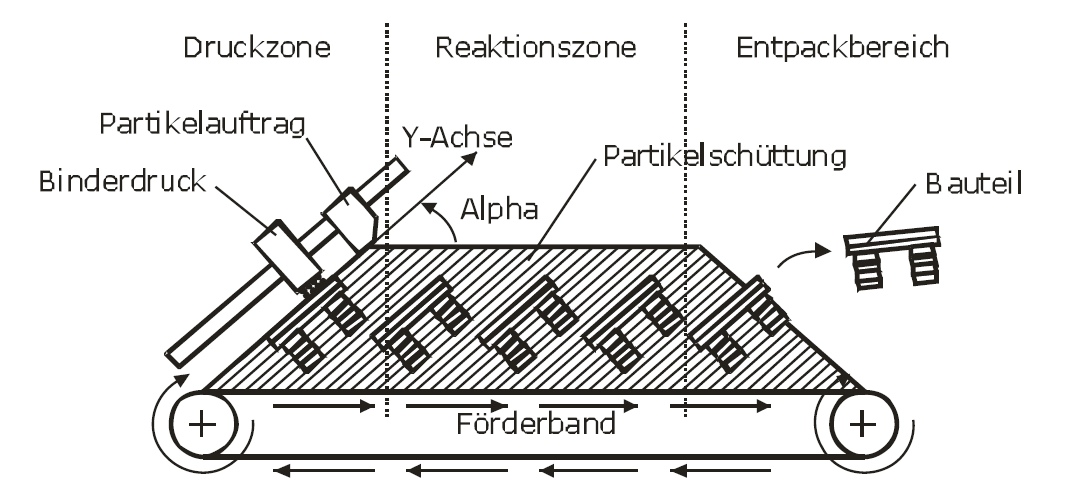

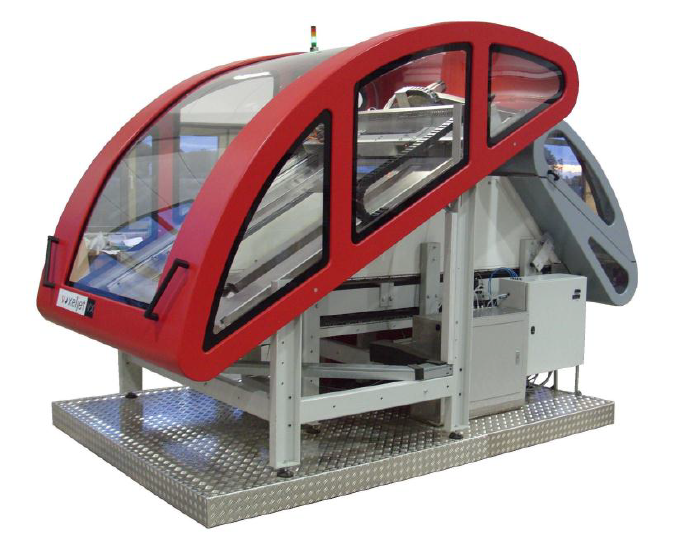

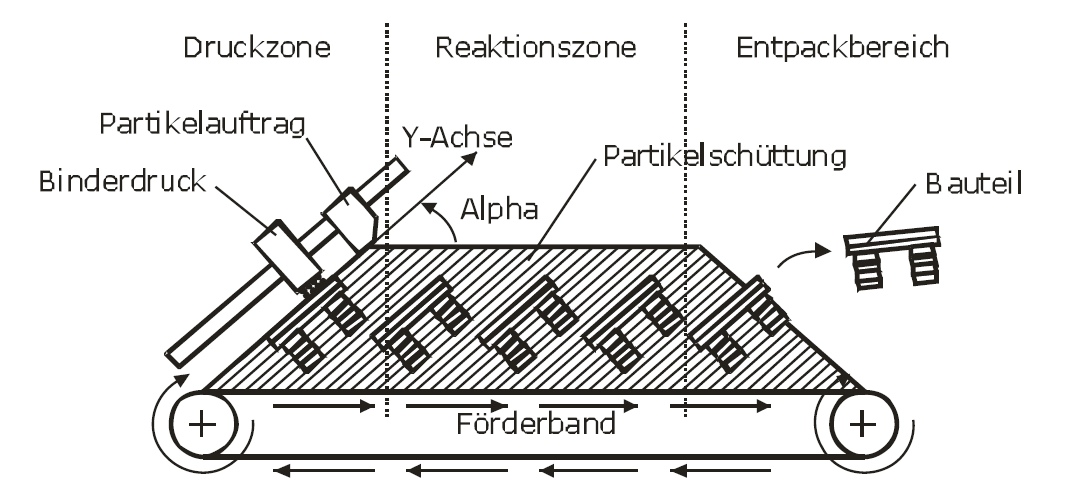

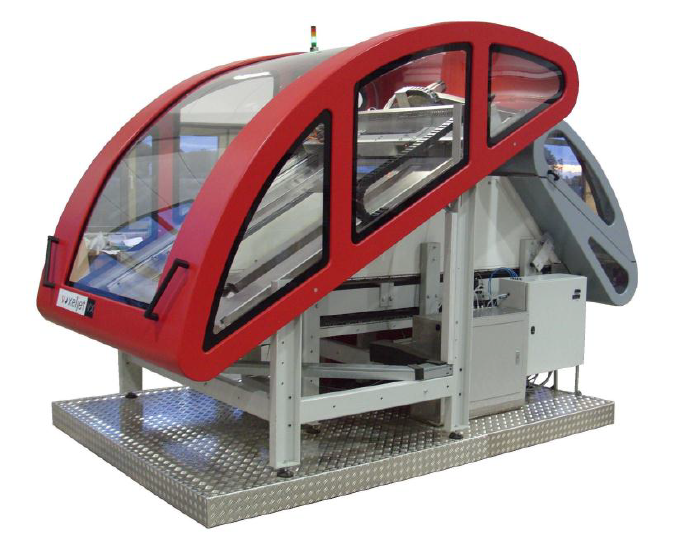

The printing system used in this research project, a voxeljet endless printer, has been adapted to the huge pressure of cemented carbide powder.

|

| Endless printer with inclined printing plane from voxeljet technology GmbH, Augsburg (From: voxeljet technology GmbH, Augsburg) |

The software system Rapix3D is the first software system that is able to handle a 3D printer with an inclined printing plane. Therefor a Parallelotop-shaped building space was realized. Also main changes regarding to the control of the machine, the job preparation and the calculation of the required layer images were achieved. Since structurally related a printer with a conveyor band has no fixed wall, a stable and easy-to-disassemble parameterized wall was developed, which is constructed during job preparation with Rapix3D and also printed later. In cooperation with software users a bunch of tools for efficient application of the new printer type were developed.

|

|

| Software system Rapix3D with inclined printing plane, Parallelotop-shaped work space and printable and removable wall |

Thus a completely new printing system, where printing and unpacking is possible at the same time, was developed in close cooperation between FORWISS and its partners.

| Supported by: Federal Ministry for Economic Affairs and Technology on the basis of a decision by the German Bundestag |

|

|

|

Project staff

Project partners