Tyre Tester

Evaluation software for a interferometric automobile tire testing device

For non-destructive testing of automobile tires the Beissbarth Automotive Group has developed a testing appliance which detects internal defects of tires at an early stage. This device operates on the basis of a shearographic interferometer recording intensity images by a CCD-camera. It measures deformations caused by slight deflations of a tire segment so that defects which are invisible to the human eye can be visualized and detected automatically. For example these defects may include separations of different layers of the shell or damages of the carcass.

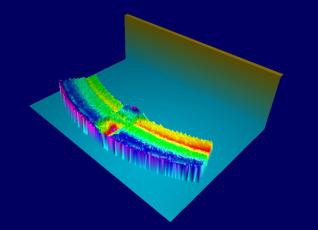

The software module developed by FORWISS evaluates the interferometric images recorded by the tire tester. First the intensity images are transformed into continuous phase images via a hybrid phase unwrapping algorithm taken over from an earlier project Single-Frame-Real-Time-Interferometry and which has been further improved regarding the execution speed and accuracy. The phase image carries information about the directional derivative of the deformation. Before the actual evaluation the phase images are masked and deskewed. The area of interest is extracted via an adaptive thresholding technique, and the deskewing is realized by non-linear optimization methods. The actual evaluation algorithm operates on the deskewed phase images. Characteristic deformation profiles are recognized and classified.

| Sample images |

|  |

| Tire with carcass damage; interferometric phase image | Resulting deformation profile; generated by the hybrid phase-unwrapping algorithm |