Intelliwood

Quality assurance in wood manufacturing by computer vision

INTELLIWOOD was a research project promoted by the European Union. It is located in the area of wood manufacturing.Partners in this consortium are small and medium enterprises, institutes of universities and large wood manufacturing companies from Europe, Australia and the U.S.

This mixture has several advantages for all partners. Knowledge will be transferred from universities, which are often accused to be "ivory towers" of science, to small and medium enterprises. These enterprises, in the case of INTELLIWOOD software engineering companies, put the knowledge into solution packages for the major wood manufacturers.

The aim of the project was to improve quality assurance in wood manufacturing and to supply an automatic wood classifier. Such classifiers exist nowadays, but the existing systems have several disadvantages: first, they use a small variety of sensors only (mostly grayvalue cameras) and not a bundle of sensors (keyword sensor-fusion), second, the methods used are standard algorithms, which are not adapted for the problems of wood manufacturing and which are often scientifically obsolete.

The research interest of FORWISS is located in the area of image vision and signal processing. FORWISS has been already active in this area for several years. The task of our research group in the project INTELLIWOOD. is to improve existing methods and to supply new approaches in this field of interest.

| Tasks of FORWISS: |

-

Classifying woods for parquets one has to exclude wood not achieving parquet quality.

In the example above the yellow marked pixels were classified as a resin pockets and the red ones as a branch. In order to detect these areas feature vectors of dimension 484 for all pixels were used. Such a mass of information contradicts any realtime capability. FORWISS developed a genetic algorithm which reduces this flood of data to a capable one, without loosing the classifying ability.

-

In many wood applications branches beginnings are not wanted. Therefore it is desirable to locate such inner branches in logs by methods of computer tomography. This allows to eliminate inappropriate wood before starting the step in production.

In the example image one can see x-ray images of several logs. The nails mark the visible beginnings of branches. By x-ray-images from several views it is possible to reconstruct the 3D progression of the branches within the inner of the wood.

-

X-ray cameras should also be used to detect sapwood on normal wood. Sapwood is the weaker layer under the bark of a tree. This wood has a lower quality and should be sorted out.

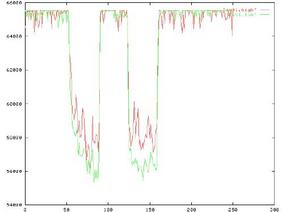

In the example image one can see a "good" part of wood (above) and and a part of wood with a higher percentage of sapwood. The graph below shows to absorption of woods along the red marked line, at an x-ray energy of 70-80 keV (green), 90-140 keV (red) respectively.

From the projects ANGIO and Optical Recycling FORWISS got expert knowledge in the area of x-ray image processing.

Leader of the projects consortium is the sensoTech GmbH company in Graz, Austria, which focuses on realtime image vision. Further partners in industrial image processing are the Swedish enterprises svedvision and Soliton Elektronik. These companies have a strong interest in improving their methods and techniques through knowledge from the academic area in which Lignum Research an university institute in Graz (Austria) is located. A pure research center is the Austrian Research Center Seibersdorf (ARCS), the largest non-university research institute in Austria. The ARCS has experiences in high speed image processing. Final users of the methods and solution packages to develop are the companies Holzelemente GmbH in Austria and the Tarkett Sommer AB in Sweden.