Pipeline inspection

Quality assurance during the production of flexible high pressure pipelines

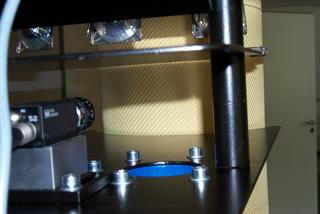

FORWISS is developing a quality control system for a woven and inner coated flexible high-pressure pipe.

The whole system consists of two parts: Part one recognizes defects and other distinctive features of the fabric whereas the second part measures the thickness and the completeness of the coating. Because the control system should work contact-free FORWISS uses a multiple-camera-system to control the fabric and the completeness of the coating. A combined sensor system consisting of a capacitive displacement sensor and an eddy current sensor is used to measure the thickness of the coating. Found defects are sent via ethernet directly to the loom-control, which will then stop the production process.

The high-pressure pipe will be used for the trenchless rehabilitation of conventional pipelines. With a new installation technology the high-pressure pipe can easily be inserted in the aging pipeline. The old pipe ist only used as a guideway. This allows the use of a high-pressure pipe with nearly the same diameter as the old pipeline.  Due to the special aramid fabric and the high-performance coating the inliner can allow a higher pressure than the pipeline pressure before the renewal.

Due to the special aramid fabric and the high-performance coating the inliner can allow a higher pressure than the pipeline pressure before the renewal.

The inliner can be inserted into the old pipeline up to a length of 3000 ft without digging up the ground. This reduces the costs for the renewal process and the down-time of the pipeline.