Deflectometry

Non-contact Inspection Method for Reflective Surfaces

The deflectometric method is suitable to inspect any reflecting surface fast and reliably. The quality of polished metal sheets and coated materials can be evaluated with regard to scratches, dents and inclusions.

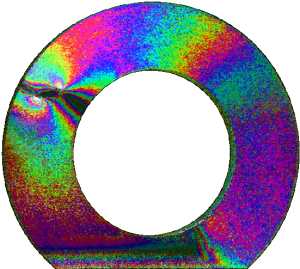

Using a single camera a number of reflected images of phase-shifted sinusoidal patters are captured. FORWISS has developed software modules which evaluate these images and compute curvature information for the object under test. These modules are now part of the deflectometry system ReflectControl of the company Micro-Epsilon Messtechnik.

The deflectometric inspection approach has many advantages. The total time of a measurement is short (a few seconds), the sensitivity is high (sub-micron), and the whole system is easy to install.

|  |

| Applications are the automotive industry and all other branches where the optical quality of the manufactured parts is important. The inspection itself can be fully automated. Expert knowledge is only necessary during the tuning phase. Therefore an unchanging quality can be guaranteed. |  |

| Our offer |

Together with our automation partner we develop a custom tailored deflectometric inspection system for you.