AktiPol

Activated polymerisation in 3D-plastic-printing

| Initial situation |

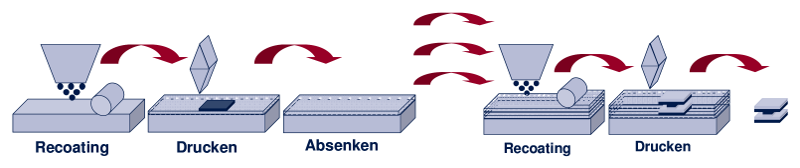

Parts printed with today's 3D-printing technique have numerous restrictions. Especially they have high porosity which leads to insufficient mechanical and thermal properties. Porosity is a result of chemical reaction of local adhesion of powder and binder components. One existing solution of this challenge is a second process step after the original printing process in which the printed parts are infiltrated with a resin.

| Goals |

Goal of the project Aktipol, "Activated polymerisation in 3D-plastic-printing", funded by the Bayerische Forschungsstiftung, is the systematic development of a single-stage process. Mechanical and thermal properties are improved by activated and extensive polymerisation. Further, the development aims the integration of mechatronic components and other locally determined properties.

|

| Proceeding |

Requirements on product, process and equipment are investigated and so basics for this new process are identified. This is followed by a consequent choice of material and analysis. Based on these research a concept for the equipment is developed. In addition, controller software is implemented that's main challenge lies in support of locally determininated properties. Deep unterstanding of the chemical processes then will be the base for a process simulation. With this and a great amount of experiments on specially designed test equipment the concept for equipment and materials is adapted and optimised. At the end of the project's duration in June of 2011, a strategy for equipment, suitable for deries production, shall be achieved..

Duration: July 1st 2008 till June 30th 2011

Funding: Bayerische Forschungsstiftung