IDe3D

Intelligent deformation compensation for 3D-printers

Current situation

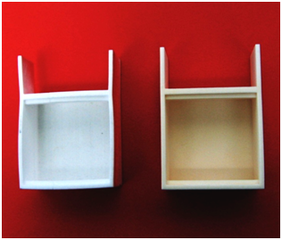

The dimensional accuracy and reproducibility of components in addition to the cost-effectiveness of an additive process is an essential criterion for the use of this technology in series production. The powder-based 3D printing offers a high potential due to the low material and process costs. The solidification of the component layers is effected by the selective introduction of a chemical binder. However, the reaction of the binder with the powder, results in a deformation of the component part. The intentional avoidance of these errors can improve the dimensional stability and enhance the economic advantage of 3D printing.

Typical deformation phenomena of 3D-printed component parts.

(Source: voxeljet technology GmbH)

Aim of the project

The goal of this project is to capture characterizable and reproducible deformation phenomena. A compensation of the deformations should be carried out before the additive manufacturing, in order to prevent errors in the dimensional accuracy of the component parts. This allows the prevention of waste and the cost of rework can be reduced. The compensation will be integrated directly into the operating software of the system. The user is referred intuitively to critical areas and has the opportunity of local predeformation of the CAD data.

Method

In this project geometry deviations are recognized and characterized using a systematic parameter variation in the 3D printing through the establishment of reference components. Based on these findings, simulation models are generated which reflect the determined deformation. By means of the gained experience and the results of the simulations, correction strategies are developed and tested. The selected strategy is implemented in the system software and its applicability shown on relevant construction processes.